Ciągły wzrost kosztów produkcji, niska cena za mleko a z tym zmniejszająca się rentowność produkcji mleka wymaga na hodowcach poszukiwania oszczędności.

Czytaj więcej

Dozowanie dodatków mineralnych za pomocą wody pitnej gwarantuje wysoką przyswajalność, mieszanki paszowe dla bydła zapewniają optymalną homogenizację oraz eliminują błąd ludzki w żywieniu krów mlecznych. Zmiana ilości dozowanych składników nie nastręcza żadnych problemów. Mieszankami paszowymi dla bydła sterujemy za pomocą pokrętła aplikacji, zgodnie z instrukcją obsługi. Aplikator może z powodzeniem stosowany być w oborach, jałownikach, wypajalniach oraz w chlewniach i kurnikach.

Zobacz produkty

Rodzaj, sposób żywienia, a przede wszystkim pojenie cieląt ma ogromne znaczenie, ponieważ wpływa na ich zdrowotność, przyszłe użytkowanie produkcyjne oraz rozpłodowe, głównie jałówek. Wszystko to decyduje z kolei o opłacalności produkcji.

Odchów cieląt jest jednym z najtrudniejszych okresów dla hodowców, a jednocześnie bardzo ważnym elementem, którego nie wolno zaniechać, ponieważ pierwsze kilka tygodni ma znamienny wpływ na rozwój układu odpornościowego i pokarmowego cielęcia.

Zobacz produkty

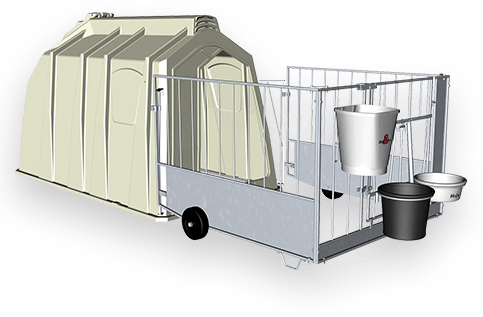

Trzymywanie cieląt w budkach igloo przynosi dla nich wiele korzyści zdrowotnych. Badania i obserwacje zwierząt przetrzymywanych w budkach na wolnym powietrzu potwierdzają skuteczność tej metody odchowu w zakresie znacznej poprawy odporności na choroby. Badania wykazały, iż cielęta odchowywane w cielętnikach zamkniętych zapadały na biegunki i zapalenia dróg oddechowych, w przeciwieństwie do cieląt utrzymywanych na powietrzu.

Zobacz produkty

Kolebką pochodzenia użytkowanego dzisiaj w handlu bydłem na świecie jest Fryzja, leżąca w większej części w Holandii. Większość liczących się europejskich populacji powstała właśnie pod wpływem bydła fryzyjskiego, importowanego przede wszystkim z tego kraju. Również polskie czarno-białe krowy stosowane w handlu bydłem zostały wytworzone w wyniku krzyżowania miejscowego bydła z bydłem fryzyjskim (pochodzącym po części także z Niemiec), a historia tego procesu liczy przynajmniej sto kilkadziesiąt lat.

Zobacz produkty

Ciąbła potrzeba poprawy wydajności mlecznej w gospodarstwa mlecznych, cechują się coraz większą potrzebą poprawy komfortu krów. Krowy średnio leżą przez 14 godzin dziennie. Każda godzina wygodnego odpoczynku to klucz do dodatkowych litrów mleka. Oznacza to, że gnojowica to wspaniały produktem ubocznych w gospodarstwach mlecznych. Suchy separat jest ciężkim i odpornym produktem, dzięki czemu idealnie nadaje się do tworzenia wygodnych legowisk dla krów. Ponadto, gnojowica jest z reguły zawsze pod ręką, już nigdy więcej nie będziesz oszczędzać na ściółce.

Zobacz produkty Chów cieląt

Chów cieląt

Ciągły wzrost kosztów produkcji, niska cena za mleko a z tym zmniejszająca się rentowność produkcji mleka wymaga na hodowcach poszukiwania oszczędności.

Czytaj więcejPomimo tego, że coraz większa rzesza hodowców przywiązuje baczną uwagę do prawidłowego żywienia cieląt siarą, obserwacje praktyczne oraz wyniki badań wskazują, że…

Czytaj więcej